Identifying choke points in the semiconductor supply chain

Manufacturing processes

The semiconductor industry is known for its so-called black boxes — deep complexities and the secretiveness of operations.

While many sectors have proprietary processes they want to keep hidden, this is especially true in chipmaking, which requires nanoscale precision, often involving many steps to make a single product. Additionally, production relies on specialized manufacturing equipment, a wide range of materials and various auxiliary materials. Unlike typical factories, where robotic arms assemble parts, semiconductor factories operate differently. In certain stages, highly automated systems move wafers through ISO Level 1 clean rooms, where large box-like machines deposit nanothin films or dissolve layers using plasma gas. These steps can be repeated hundreds of times, transforming a highly complex scientific process into a form of mass production. Indeed, the industry requires extraordinary precision and advanced technology. For example, one such technique is so precise that if one were to — hypothetically — create a mirror as large as the landmass of Germany, the surface deviation would be smaller than 0.1 millimeters. Another is able to repeatedly beam lasers at 50,000 times per second to vaporize tiny droplets of molten tin and produce plasma at 500,000 degrees Celsius. The picture becomes even more complex when it comes to critical mineral export controls, as seen recently with restrictions on gallium, germanium, antimony and tungsten, among others. Should export restrictions target a particular mineral, only a few companies would have the wherewithal to address resulting supply chain issues. Without adequate economic security preparations, Japan could face disruptions in semiconductor material production, creating potential “choke points” — originally a military term that refers to a critical juncture in which a supply chain’s flow is blocked. For vital industries, these bottlenecks pose national-level risks. Acknowledging this, the Japanese government has designated semiconductors as a critical commodity under the Economic Security Promotion Act, backing efforts to expand manufacturing, reinforce reserves and secure alternative resources. Another unique aspect of semiconductor manufacturing is the small number of companies and specialists involved. Unlike most industries, where many competitors across advanced economies accumulate technology and expertise over time, only a few firms, such as Taiwan Semiconductor Manufacturing Co., Intel, Samsung Electronics and SK Hynix are capable of producing the most advanced chips. As for semiconductor manufacturing equipment, ASML in the Netherlands is the only company capable of producing the extreme ultraviolet lithography machines essential for the most advanced chip production. Other critical processes, such as deposition, etching, cleaning and inspection, rely on equipment produced by just two or three companies worldwide, with limited production capacity. While semiconductors are mass-produced, the machines that manufacture them are made in small quantities and many essential materials are supplied by only a handful of firms. This concentration of expertise and production creates another black box, where crucial know-how is closely guarded — reinforcing potential choke points.

Public-private collaboration

Japan remains a key player in chip manufacturing. Although it chose not to pursue advanced-node semiconductor production in the past, many companies and researchers in the country still hold critical knowledge about manufacturing equipment and materials. This expertise is a valuable asset, and it is essential for Japan to consolidate this knowledge to strengthen its economic security. However, the complexity of semiconductor production makes fully understanding and addressing these issues difficult. Economic security is largely a government-led effort due to its national importance, but accurate assessments and the development of effective countermeasures require close cooperation with the private sector. Unlike regulatory domains, where rules can be enforced, it is not possible to compel companies to share business secrets.

Additionally, companies may hesitate to share information if they are not sure whether they could be negatively impacted.

Public-private cooperation inherently involves bringing together conflicting elements, such as national-level interests and those of shareholders. While Western corporate models focus on short-term shareholder returns and authoritarian regimes prioritize national interests over company profits, Japan’s corporate system emphasizes sustainability and societal contributions. As a result, Japanese companies should view economic security as a matter of self-interest and adopt a long-term perspective. This alignment would help government policies on economic security be more effective and maximize the impact of public-private cooperation. The government is working on implementing a law that allows the sharing of government-held classified information with the private sector but does not yet cover privately held classified information. For public-private collaboration to succeed, it is crucial to establish this as a practical mechanism.

However, more progress is needed to include sensitive private-sector information on semiconductor supply chains. The government is also conducting initiatives such as collecting technology management best practices and creating new public-private dialogue frameworks under an action plan to strengthen economic security-related industrial and technological foundations. To ensure the success of these efforts, the government must focus on several key areas: Strictly managing sensitive information from private companies, avoiding regulations or policies that could disadvantage companies willing to share information and finally, prioritizing diplomatic negotiations, financial support and regulatory measures that individual companies cannot address on their own, rather than imposing industry-wide restructuring measures. Creating an environment where companies feel secure in sharing information is critical. At the same time, businesses must adopt a long-term perspective and share relevant material with designated public officials, allowing the government to develop targeted, effective measures. While firms may naturally be cautious, failing to establish long-term national strategies could harm Japan as a whole, including its private sector. To sustain economic security, it is important to address choke points in semiconductor manufacturing through public-private collaboration that, in turn, should be driven by a shared commitment to national defense — without coercion from the state or pressure to conform within the industry.

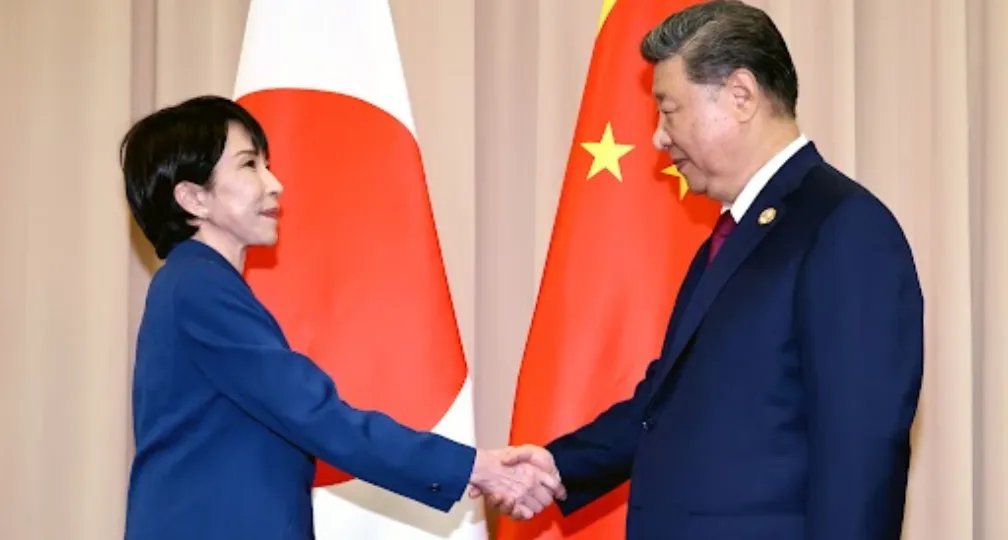

(Photo Credit: Shutterstock)

[Note] This article was posted to the Japan Times on Apri 4, 2025:

https://www.japantimes.co.jp/commentary/2025/04/04/japan/semiconductor-supply-chain-critical-points/

Geoeconomic Briefing

Geoeconomic Briefing is a series featuring researchers at the IOG focused on Japan’s challenges in that field. It also provides analyses of the state of the world and trade risks, as well as technological and industrial structures (Editor-in-chief: Dr. Kazuto Suzuki, Director, Institute of Geoeconomics (IOG); Professor, The University of Tokyo).

Disclaimer: The opinions expressed in Geoeconomic Briefing do not necessarily reflect those of the International House of Japan, Asia Pacific Initiative (API), the Institute of Geoeconomics (IOG) or any other organizations to which the author belongs.

Visiting Senior Research Fellow

Eiki Tagami is a visiting senior research fellow in Institute of Geoeconomics at International House of Japan from May 2024. With over 30 years of experience at a Japanese trading house, Mr. Tagami has specialized in risk management and industry analysis. From 2006 to 2017, he worked at a think tank within the trading house, covering a wide range of industry analysis work with a particular focus on value-chain analysis. In 2021, he was appointed to be in charge of economic security in the trading house. He completed the Executive Management Program at the University of Tokyo and holds a BA in Political Science from Waseda University

View Profile-

Fed-Treasury Coordination as Economic Security Policy2026.02.13

Fed-Treasury Coordination as Economic Security Policy2026.02.13 -

What Takaichi’s Snap Election Landslide Means for Japan’s Defense and Fiscal Policy2026.02.13

What Takaichi’s Snap Election Landslide Means for Japan’s Defense and Fiscal Policy2026.02.13 -

Challenges for Japan During the U.S.-China ‘Truce’2026.02.12

Challenges for Japan During the U.S.-China ‘Truce’2026.02.12 -

India and EU Sign Mother of All Deals2026.02.09

India and EU Sign Mother of All Deals2026.02.09 -

Orbán in the Public Eye: Anti-Ukraine Argument for Delegitimising Brussels2026.02.04

Orbán in the Public Eye: Anti-Ukraine Argument for Delegitimising Brussels2026.02.04

Orbán in the Public Eye: Anti-Ukraine Argument for Delegitimising Brussels2026.02.04

Orbán in the Public Eye: Anti-Ukraine Argument for Delegitimising Brussels2026.02.04 Fed-Treasury Coordination as Economic Security Policy2026.02.13

Fed-Treasury Coordination as Economic Security Policy2026.02.13 When Is a Tariff Threat Not a Tariff Threat?2026.01.29

When Is a Tariff Threat Not a Tariff Threat?2026.01.29 Oil, Debt, and Dollars: The Geoeconomics of Venezuela2026.01.07

Oil, Debt, and Dollars: The Geoeconomics of Venezuela2026.01.07 India and EU Sign Mother of All Deals2026.02.09

India and EU Sign Mother of All Deals2026.02.09